New business models and sustainability

We had good reasons to participate in Maintenance in Antwerp: it’s the show where many production companies go to find new partners and vendors. Mainly for hardware, but the presence of a Software and Digitizations Zone clearly shows that, in manufacturing too, products, these days, are quickly turning into services. At Maintenance, this was also illustrated by the presence of our customer AquaSecurity. This leading manufacturer of fire protection and sprinkler systems has been using our Inimco.Facts for some time now. Inimco.Facts allowed them to develop a new business model and offer their customers predictive maintenance. As you can learn from their customer story, offering these new services goes hand in hand with sustainability.

Sustainability was a topic that many presenters addressed in their master classes and talks during Maintenance. The production sector is one of the industries hardest hit by surging energy prices due to geopolitical unrest. Any measure that can contribute to more efficient production and lower energy consumption is a bonus in the current environment.

Streamline your assets

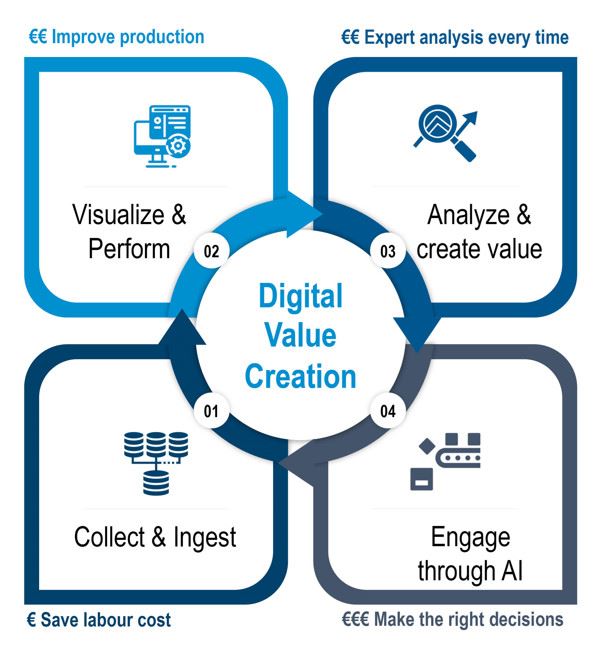

We brought a strong message to the visitors of Maintenance: streamline your assets by centralizing production data and by adding predictive insights. We illustrated that with a visual – it shows exactly what to do to create value for our customers through digitization.

We keep hearing from customers needing to get all their data centralized in order to have a good overview of all that is happening on their production floor, often across multiple sites in many countries. That is the core function of our Facts platform: gathering data from different sources and presenting them in easy-to-use dashboards. That way it is easy to check the performance of different machines and adjust settings, to deliver top-quality product at the lowest price.

Innovating with Artificial Intelligence

By adding Artificial Intelligence (AI) to the mix, production companies can get even better results, and that is where our sister company Yazzoom comes in, with its award-winning product Yanomaly. Yanomaly can monitor assets such as pumps, compressors, motors and AI algorithms will learn, for each equipment individually, how they normally behave. When anomalies are detected in their functioning, an alert is raised to plan an intervention. The beauty of the product is that it allows companies to build machine-learning models that predict failures and product quality issues and deploy these in production. No wonder then that BEMAS recognized Yanomaly with a Digital Innovation Award during the Maintenance conference.

With our adjacent booths at Maintenance, Inimco and Yazzoom again demonstrated the power of the PA Solutions ecosystem. By combining our offerings, we can deliver a complete solution for any production company that wants to streamline its assets, centralize its data and implement predictive maintenance.

Contact us – you are ready to ride on the next digitization wave!